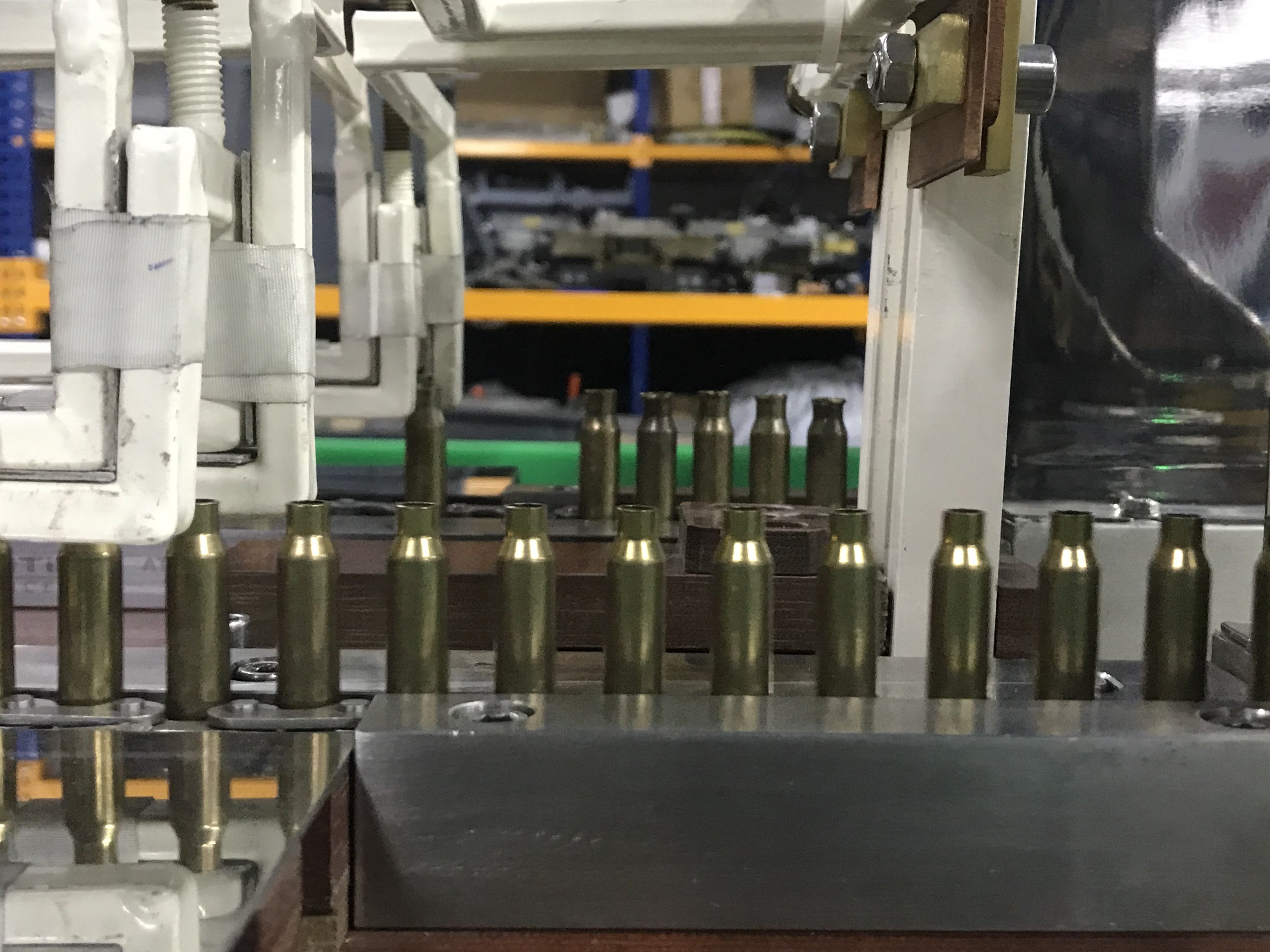

Working with 2 machines in the domestic cartridge production line of Makine ve Kimya Endüstrisi AŞ (MKE AŞ), Hidrotim Mühendislik AŞ made more than 30 deliveries to different users in the country with the fastest machines in its field. The company, which started exporting, aims to reach an export figure of close to 100 percent in 5 years.

Hüseyin Aydın, Chairman of the Board of Hidrotim Mühendislik AŞ, told Anadolu Agency (AA) that they have been producing mainly on R&D since 2011.

Stating that they carry out works for various sectors, especially mining and defense, Aydın stated that they have signed very special machines and productions for customers such as ASELSAN and TUSAŞ.

Aydın stated that the adventure of entering ammunition production line machines in the defense industry started with MKE AŞ, and said:

“With the use of our machines in the Gazi Fişek Factory, other domestic manufacturers in Turkey also found us. We have manufactured more than 30 machines with different features for various companies until today, our productions are still continuing. We continue our projects both in Turkey and abroad. We participated in many fairs in the country and abroad this year. We both followed the industry closely and tried to explain our machines.”

“We reduced the caliber change to 10 minutes”

Aydın said that when they entered the sector, they encountered companies with 20, 30, 50 years in this field in the world, and that quality and lower prices were not enough to compete with them.

Emphasizing that they have added innovations to machines with their engineering and R&D power from the past, Aydın said:

“As a result, we have developed the world’s fastest caliber change induction annealing machine. The most important feature of the machine is its feeders. At the same time, 5.56×45 and 7.62×51 millimeter caliber sleeves can be fed easily without changing any apparatus, the machine has the feature of feeding 2 calibers at the same time. This feature How did it reflect on our machine?Under normal conditions, the transition from one caliber to the other takes approximately 4 to 6 hours. In our machine, you can switch from one caliber to another caliber by changing 1-2 very small parts, as you don’t need to make any changes regarding the feeders and equipment. This time is about 10 I can say minutes. We reduced the caliber change from 4-6 hours to 10 minutes. This made our machine the world’s fastest calibrating induction annealing machine. We exhibited this machine in one of the big defense fairs in Germany in March. urea We have received a great deal of attention from manufacturers to our machine. Our negotiations with companies continue. We will exhibit our products in the USA next year. Our aim is to introduce and sell our machines, which we produce locally and nationally and which have some firsts in terms of features, to all over the world. Apart from the potential business in Turkey, our goal is to export nearly 100 percent of our products after 5 years.”

The goal is to produce the entire line

Aydın said that they can still produce 7-8 of the machines used in the cartridge production line, and that their aim is to reach the point where they can produce the entire line consisting of tens of machines.

Stating that they studied the lessons related to ammunition production while designing the machines, Aydın stated that learning the process very well beyond the design R&D at the desk also enables the emergence of machines that make a difference. Intellectual, “We work very seriously on the whole process from the starting point of the rice to the final product. There are hundreds of oven manufacturers in Turkey and around the world, and they serve many sectors. We only produce ovens and special washing machines for ammunition. What we do is for and how it should be done. And since we know very well what product should come out in the end, we design our machines in this direction down to the smallest detail. Since we know that the work we do when producing machines is not just a machine, but an ammunition, we produce our machines by studying very well, we do R&D.” said.

Emphasizing that this approach also reflects positively on the efficiency of the machines they produce, Aydın stated that while the machines in the sector operate with 80-90 percent efficiency, their own machines reach 100 percent efficiency. Intellectual, “You can get 210-220 products at 90 percent efficiency from an induction annealing machine with a production capacity of 240 pieces per minute. Our machines work with 100 percent efficiency. In fact, the capacity of our newly produced feeders can work much higher than that, we can even increase this capacity if we want.” he said.